Published in Dhaka Tribune on Thursday, 26 December 2013.

Apparel raw materials use falls sharply

Ibrahim Hossain Ovi

Industry insiders say it’s a lagged impact of factory disasters; political unrest is a catalyst

The orders for apparel products registered decline as the country’s readymade garment industry witnessing a lagged impact of Rana Plaza collapse and Tazreen Fashion fire incident, industry insiders said.

The ongoing political unrest has intensified the crisis.

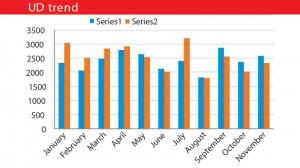

Their assessment is based on the recent trend of utilisation declaration (UD) of raw materials – BGMEA maintains for its members who use the materials tax-free under a bonded warehouse mechanism.

Number of UDs reflects the trend of production to be performed.

According to Bangladesh Garment Manufacturers and Exporters Association (BGMEA), factory owners obtained 8,706 UDs in August-November period, which is 9.5% lower than 9,625 UDs obtained during the same period last year.

“Two of my buyers have shifted on excuse of fire and building safety issues. Buying orders are moving and it may continue in the days ahead,” said Shabbir Mostafa, a BGMEA director.

Before placing orders, the buyers say building compliance, including fire safety, is a must while they are unwilling to take orders from shared buildings, he added.

Rana Plaza incidents left the garment sector into crises, tarnishing the industry image as the buyers did not think about building safety before the incident, said Mostafa, also MD of Raozan Sweater Limited.

“After the disaster, the buying orders saw down trend due to bad image,” said Syed Sadek Ahmed, another BGMEA director.

The buyers are moving elsewhere due to the fire and building safety as well as price competitiveness.

He said the production cost has increased due to low productivity of workers while our competitor is producing more products by employing same number of workers.

The global demands are showing up and down due to economic recession, which might pull down the buying orders, said Khandaker Golam Moazzem of Centre for Policy Dialogue, a civil society think-tank.

“It’s a reflection of Rana Plaza and Tazreen Fashion disasters,” Exporters Association Bangladesh (EAB) President Abdus Salam Murshedy told the Dhaka Tribune.

Impact of Rana Plaza disaster began surfacing after five months as the execution of an order becomes effective at least four month later, he said

To escape the adverse impact, Bangladesh has to make RMG sector stable by ensuring fire and building safety standards, he added.

If the global retailers’ brands work with Bangladesh government and BGMEA to improve the fire and building safety, it will be a certificate for the RMG sector, which will also brand Bangladeshi products, said Murshedy, also former president of BGMEA.

“Political violence ahead of the general election works as a catalyst to slowing down the orders,” said BGMEA Vice President Reaz Bin Mahmood.

He said safety and security aspect was another reason. “It’s a great challenge for the RMG sector to remain connected with the buyers.”

According to BGMEA, around 44 lakh workers are employed in the industry, 80% of them are women.

The export earnings of $21.5bn from the sector contributes 10% to the country’s GDP.